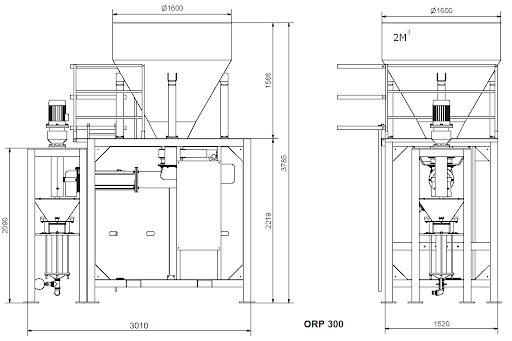

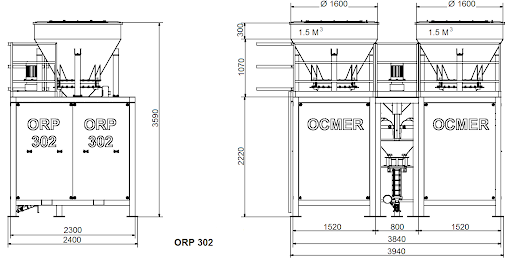

ORP-300 and ORP-302

Plants for Tundishes' Ordinary Maintenance into Steel Mills

Main features

-

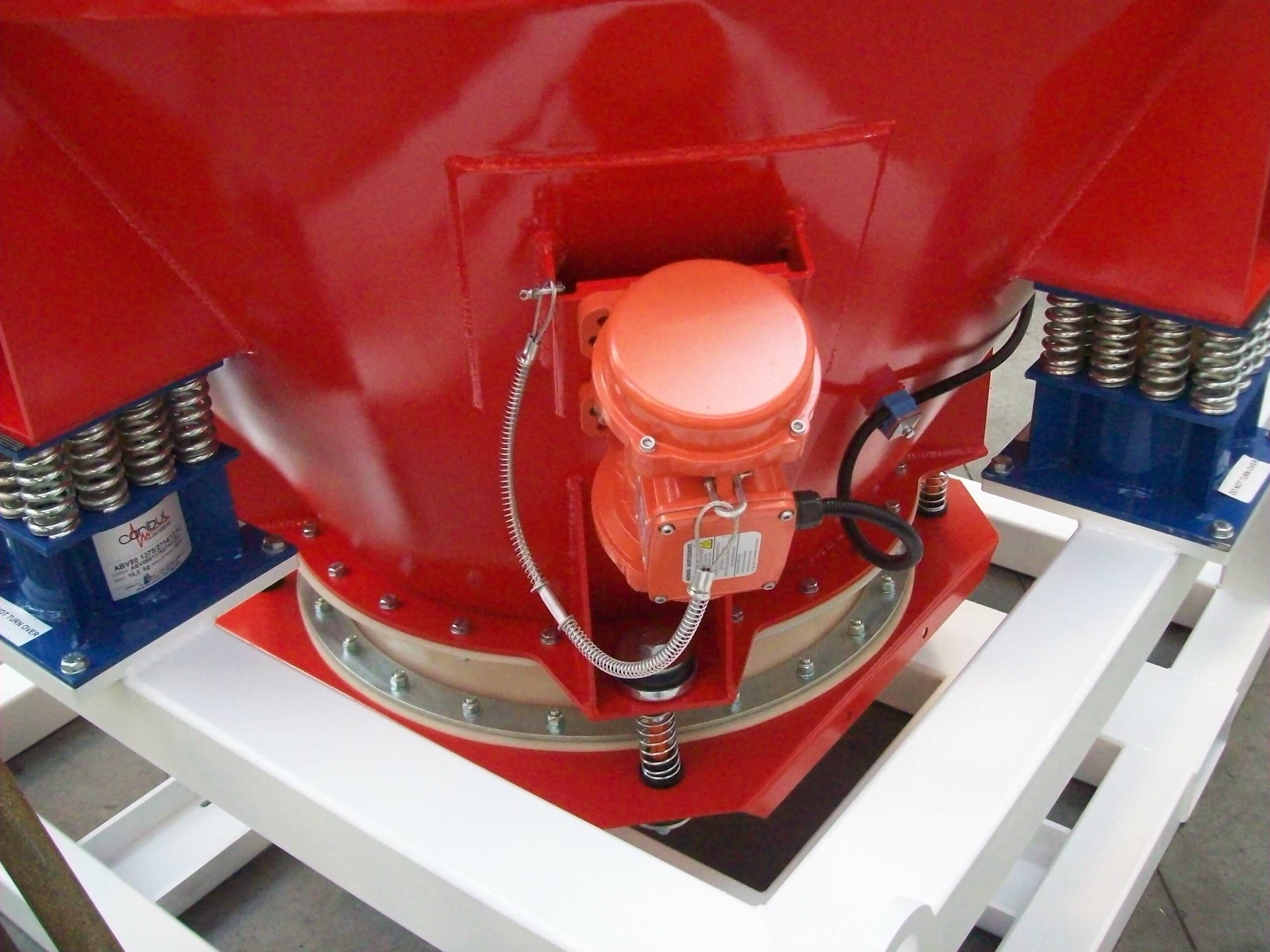

Robust and reliable

-

Modular

-

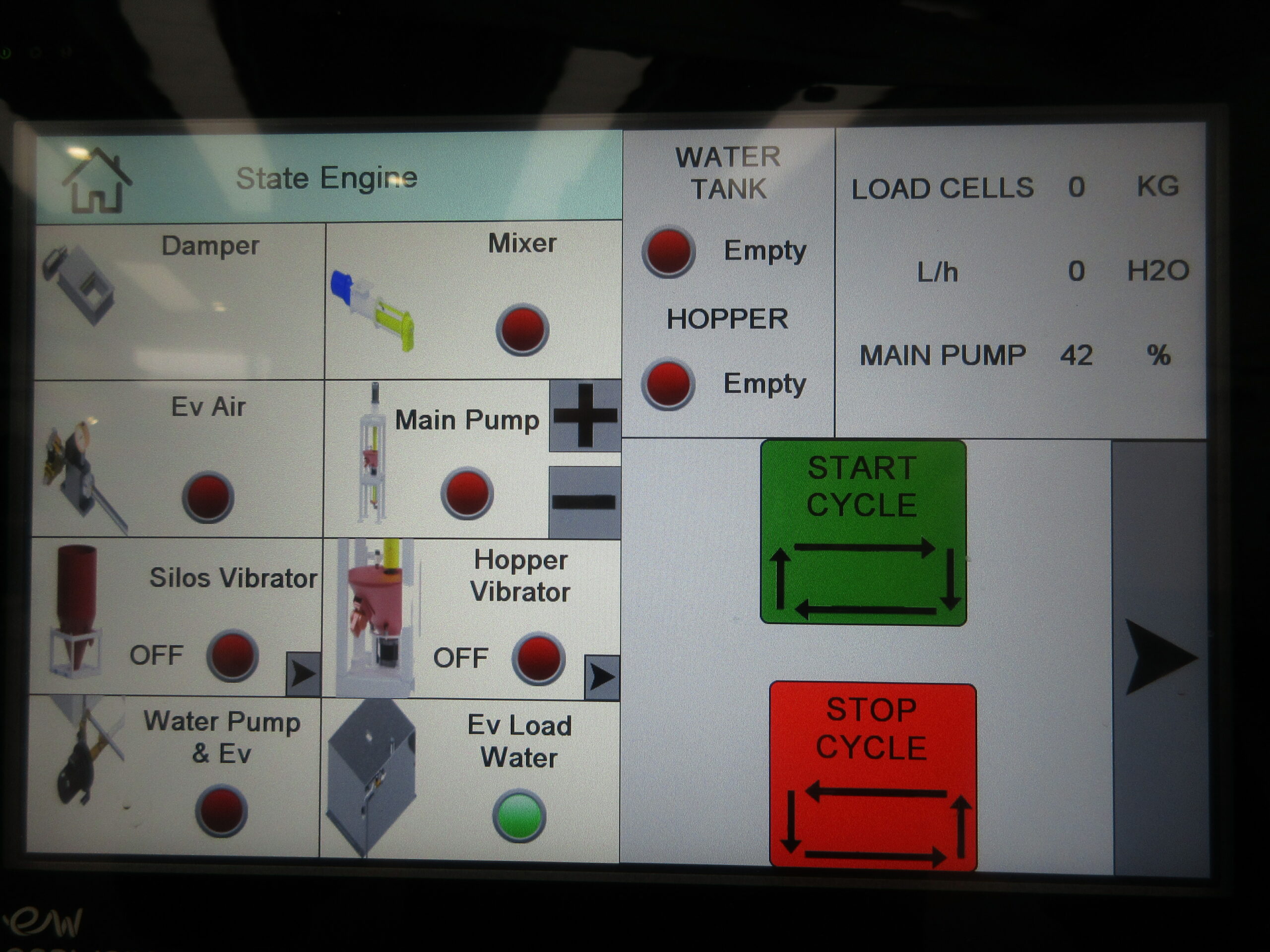

Automatic start-up and shutdown cycles

-

Accurate water dosing also at controlled temperatures

-

Adjustable flow rate

-

Low and easy to carry out maintenance

WEIGHTS

Kg. 1.650 (ORP 300)

Kg 2.400 (ORP 302)

Technical data

- Range: adjustable up to a maximum of 4 M3/h

- PPressure: up to 30 bars

- Pumpable grain size: up to 6 mm

- Water dosing from 300 to 1600 liti/h

- Silo capacity: 1.5 - 2 M3 (other cubages on request)

Do you want more information or have any requests? Fill out the form with your information and questions. Our team will be happy to help you and will contact you as soon as possible!

Address

OCMER Co. srl – Partita IVA: IT08959020150

Via 1° Maggio, 33, 20014 Nerviano (MI) Italy

Phone

+39 0331 415221